Key Takeaways

- The PDCA cycle is a powerful tool for driving continuous improvement in any organization.

- To master the PDCA cycle, it’s important to follow the four steps of Plan, Do, Check, and Act, and invest in resources and tools for data collection and analysis.

- Overcoming common challenges like lack of data, resistance to change, and inadequate resources is crucial to successfully implementing the PDCA cycle and achieving long-term success.

Are you tired of making the same mistakes in your business operations, or not being able to achieve the results you want?

Do you want to improve your team’s problem-solving skills and foster a culture of continuous improvement?

Look no further than the PDCA cycle.

PDCA, or Plan-Do-Check-Act, is a simple yet powerful framework that can help organizations of all sizes and industries improve their processes, products, and services.

By following a step-by-step approach that involves planning, executing, evaluating, and improving, the PDCA cycle enables businesses to identify and address areas for improvement systematically, ensuring that each cycle builds upon the last.

In this comprehensive guide, we’ll take a deep dive into the PDCA cycle and provide you with a step-by-step guide to mastering it.

You’ll learn how to identify and define the problem, analyze the current situation, develop potential solutions, select the best one, and implement an action plan.

We’ll also explore how to evaluate your results, take corrective action, and standardize your processes for continuous improvement.

Whether you’re a business owner, manager, or team leader, this guide will provide you with the tools and strategies you need to implement the PDCA cycle in your organization and foster a culture of continuous improvement.

So let’s dive in and start mastering the PDCA cycle today.

Before we venture further into this article, we like to share who we are and what we do.

About 9cv9

9cv9 is a business tech startup based in Singapore and Vietnam with a strong presence all over the world.

With over six years of startup and business experience, and being highly involved in connecting with thousands of companies and startups, the 9cv9 team has listed some important learning points in this overview of how to master the PDCA cycle for your business and company.

If you are looking for a job, we welcome you to apply for a job at 9cv9 now.

Mastering the PDCA Cycle: A Step-by-Step Guide to Continuous Improvement

- Understanding the PDCA Cycle

- Benefits of using PDCA Cycle

- Step-by-Step Guide to Mastering the PDCA Cycle: Plan

- Step-by-Step Guide to Mastering the PDCA Cycle: Do

- Step-by-Step Guide to Mastering the PDCA Cycle: Check

- Step-by-Step Guide to Mastering the PDCA Cycle: Act

- Common Challenges in the PDCA Cycle and How to Overcome Them

1. Understanding the PDCA Cycle

The PDCA cycle, also known as the Deming cycle or the Shewhart cycle, is a framework for continuous improvement that has been widely used in quality management, project management, and business operations.

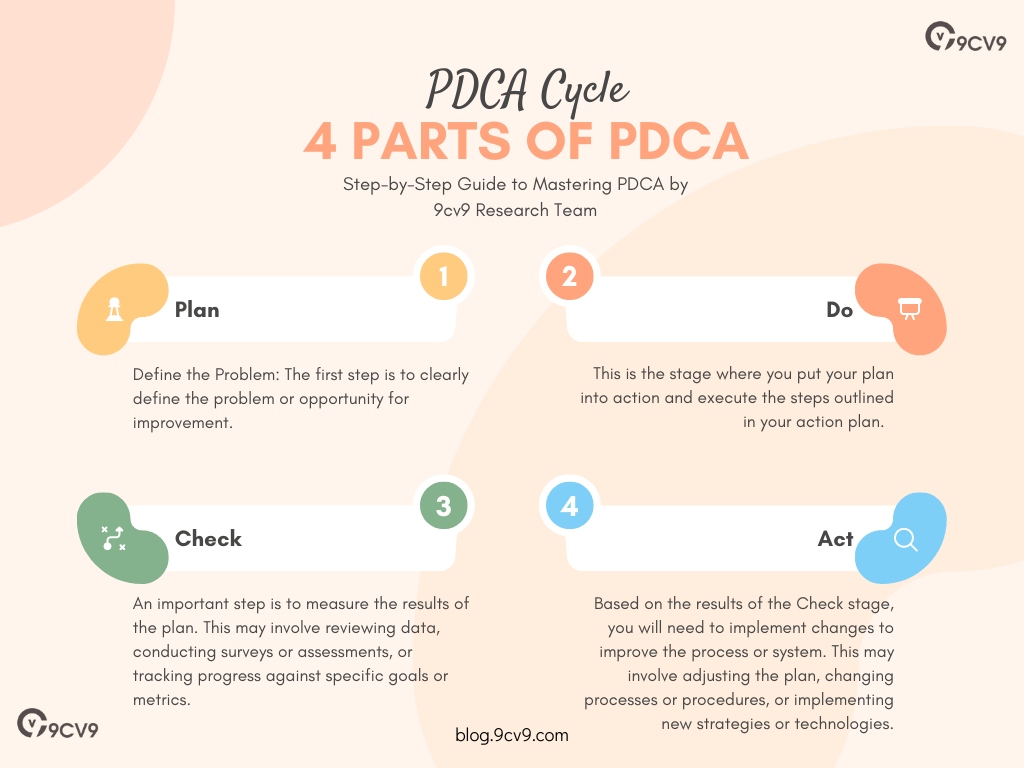

The PDCA cycle consists of four key stages: Plan, Do, Check, and Act.

The first stage, Plan, involves identifying the problem or opportunity for improvement and developing a plan to address it.

This includes analyzing the current situation, defining the problem, identifying potential solutions, selecting the best solution, and developing an action plan.

The second stage, Do, involves implementing the action plan and documenting the process.

This stage is all about executing the plan and putting it into action.

The third stage, Check, involves measuring and evaluating the results of the action plan.

This includes comparing the actual results to the expected outcomes and identifying any gaps, and opportunities for improvement.

The final stage, Act, involves taking corrective action based on the results of the evaluation.

This includes implementing changes to the process or plan, standardizing the process, and continuing to monitor and improve it.

The PDCA cycle is designed to be a continuous process, with each cycle building upon the last.

By following this cycle, organizations can identify and address areas for improvement systematically, ensuring that their operations, products, and services are always getting better over time.

Overall, the PDCA cycle is a simple yet effective framework for continuous improvement that can help organizations of all sizes and industries achieve their goals and stay competitive in today’s ever-changing business landscape.

2. Benefits of using PDCA Cycle

The benefits of using the PDCA cycle for continuous improvement include:

- Increased Efficiency: The PDCA cycle helps to identify inefficiencies in processes and systems, leading to improvements that result in increased efficiency and productivity.

- Better Quality: By focusing on identifying and addressing the root causes of problems, the PDCA cycle leads to better-quality products, services, and processes.

- Cost Savings: Through the identification and elimination of waste, the PDCA cycle helps to reduce costs and improve profitability.

- Employee Engagement: Involving employees in the PDCA cycle fosters a culture of continuous improvement and encourages employee engagement and ownership in the process.

- Customer Satisfaction: The PDCA cycle helps to identify and address customer needs and expectations, leading to improved customer satisfaction and loyalty.

- Innovation: The PDCA cycle encourages experimentation and innovation, leading to new ideas and solutions that can drive growth and competitiveness.

- Data-Driven Decision-Making: The PDCA cycle relies on data collection and analysis to inform decision-making, leading to more informed and effective decision-making.

Overall, the PDCA cycle provides a structured approach to continuous improvement that can lead to numerous benefits for organizations of all sizes and industries.

3. Plan

The Plan stage of the PDCA cycle is the first step in the process of continuous improvement.

During this stage, you will identify the problem or opportunity for improvement and develop a plan to address it. This stage involves several key steps, including:

- Define the Problem: The first step is to clearly define the problem or opportunity for improvement. This may involve gathering data, analyzing processes, or conducting surveys or interviews to identify areas of inefficiency, waste, or other issues.

- Analyze the Current Situation: Once you have identified the problem or opportunity for improvement, the next step is to analyze the current situation. This may involve reviewing data, observing processes, or conducting a root cause analysis to understand the underlying issues.

- Identify Potential Solutions: After analyzing the current situation, you can then begin to brainstorm potential solutions to the problem or opportunities for improvement. This may involve considering different approaches, technologies, or processes that could help address the issue.

- Select the Best Solution: Once you have identified potential solutions, the next step is to evaluate them and select the best one. This may involve conducting a cost-benefit analysis, weighing the pros and cons of each solution, or consulting with stakeholders to ensure that the chosen solution is the best one for your organization.

- Develop an Action Plan: Finally, you will need to develop an action plan to implement the chosen solution. This may involve setting specific goals, outlining the steps required to achieve those goals, and assigning responsibilities to team members to ensure that the plan is executed effectively.

Overall, the Plan stage of the PDCA cycle is critical for ensuring that your organization is focused on the right problem or opportunity for improvement and has a clear plan in place to address it.

By taking a systematic approach to problem-solving and decision-making, you can ensure that your organization is moving in the right direction and making progress toward your goals.

4. Do

The Do stage of the PDCA cycle is where the rubber meets the road.

This is the stage where you put your plan into action and execute the steps outlined in your action plan.

The Do stage involves several key steps, including:

- Communicate the Plan: Before you start executing the plan, it’s essential to communicate it clearly to all team members involved. This may involve holding a meeting or briefing to ensure that everyone is aware of their roles and responsibilities and has a clear understanding of what needs to be done.

- Implement the Plan: Once everyone is on board and aware of the plan, it’s time to start implementing it. This may involve taking specific steps, such as purchasing new equipment, training employees, or changing processes to ensure that the plan is executed effectively.

- Document the Process: As you implement the plan, it’s essential to document each step of the process. This may include keeping track of any challenges or issues that arise, noting any changes to the plan or timeline, and documenting any successes or milestones achieved.

- Monitor Progress: Throughout the Do stage, it’s critical to monitor progress and ensure that the plan is being executed according to the action plan. This may involve conducting regular check-ins with team members, reviewing data or reports, or tracking progress against specific goals or metrics.

- Adjust as Needed: Finally, it’s important to be flexible and adjust the plan as needed. If unexpected issues or challenges arise, it may be necessary to make adjustments to the plan or take corrective action to keep the project on track.

Overall, the Do stage of the PDCA cycle is where the real work happens, and progress toward your goals is made. By focusing on execution, documentation, monitoring, and adjustment, you can ensure that your plan is executed effectively, and that you are making progress toward achieving your desired outcomes.

5. Check

The Check stage of the PDCA cycle is where you evaluate the results of the plan and measure progress toward your goals.

This stage involves several key steps, including:

- Measure Results: The first step in the Check stage is to measure the results of the plan. This may involve reviewing data, conducting surveys or assessments, or tracking progress against specific goals or metrics.

- Compare Actual Results to Expected Outcomes: Once you have measured the results, the next step is to compare the actual results to the expected outcomes. This may involve analyzing data, identifying any gaps or discrepancies, and assessing the effectiveness of the plan.

- Identify Opportunities for Improvement: Based on your analysis, you can then identify any opportunities for improvement. This may involve looking for areas where the plan fell short, identifying gaps in knowledge or resources, or assessing the effectiveness of specific strategies or tactics.

- Take Action: Finally, you will need to take corrective action based on the results of your evaluation. This may involve adjusting the plan, implementing new strategies, or making changes to processes or procedures to ensure that future efforts are more effective.

Overall, the Check stage of the PDCA cycle is critical for ensuring that you are making progress toward your goals and achieving the desired outcomes. By measuring results, comparing actual results to expected outcomes, identifying opportunities for improvement, and taking corrective action, you can ensure that your organization is constantly improving and making progress toward its goals.

6. Act

The Act stage of the PDCA cycle is where you take what you have learned from the Check stage and make changes or adjustments to improve the process or system.

This stage involves several key steps, including:

- Implement Changes: Based on the results of the Check stage, you will need to implement changes to improve the process or system. This may involve adjusting the plan, changing processes or procedures, or implementing new strategies or technologies.

- Test the Changes: Once you have implemented changes, it’s important to test them to ensure that they are effective. This may involve running simulations, conducting pilot tests, or gathering feedback from stakeholders to ensure that the changes are working as intended.

- Monitor Progress: As you implement changes, it’s important to monitor progress and ensure that the changes are having the desired effect. This may involve reviewing data, tracking progress against specific goals or metrics, or conducting assessments to measure the impact of the changes.

- Adjust as Needed: Finally, it’s important to be flexible and adjust the changes as needed. If unexpected issues or challenges arise, it may be necessary to make additional adjustments to ensure that the process or system is working effectively.

Overall, the Act stage of the PDCA cycle is critical for ensuring that your organization is constantly improving and making progress toward its goals.

By implementing changes, testing their effectiveness, monitoring progress, and making adjustments as needed, you can ensure that your organization is adapting to changing circumstances and achieving the desired outcomes.

7. Common Challenges and How to Overcome Them

The PDCA cycle is a powerful tool for continuous improvement, but like any process, it can present challenges.

Some of the most common challenges organizations face when implementing the PDCA cycle include:

- Lack of Data: One of the most significant challenges in the PDCA cycle is a lack of data. Without accurate data, it’s difficult to measure progress, identify opportunities for improvement, or make informed decisions about changes to the process or system. To overcome this challenge, organizations must invest in data collection and analysis tools to ensure that they have the data they need to drive the PDCA cycle.

- Resistance to Change: Another common challenge is resistance to change. Implementing the PDCA cycle often requires significant changes to processes, procedures, or systems, and some employees may be resistant to these changes. To overcome this challenge, it’s important to communicate the benefits of the changes clearly and involve employees in the process to ensure that they understand the rationale behind the changes.

- Lack of Accountability: Without clear accountability, it can be challenging to ensure that the PDCA cycle is implemented effectively. To overcome this challenge, organizations must establish clear roles and responsibilities, assign ownership for each step of the process, and hold team members accountable for their actions.

- Inadequate Resources: Implementing the PDCA cycle effectively requires resources, including staff time, technology, and funding. Without these resources, it can be challenging to make the necessary changes to the process or system. To overcome this challenge, organizations must invest in the resources necessary to support the PDCA cycle and ensure that they are allocated effectively.

- Siloed Departments: Finally, siloed departments can present a significant challenge when implementing the PDCA cycle. When departments work in isolation, it can be difficult to share data, identify opportunities for improvement, or implement changes effectively. To overcome this challenge, it’s important to encourage collaboration and communication across departments to ensure that the PDCA cycle is implemented effectively.

The PDCA cycle can be a powerful tool for continuous improvement, but it is not without its challenges.

By investing in data collection and analysis tools, communicating the benefits of changes clearly, establishing clear roles and responsibilities, allocating resources effectively, and encouraging collaboration across departments, organizations can overcome these challenges and implement the PDCA cycle effectively.

Also, read our hiring guides and workplace tips for Southeast Asia

- Vietnam: How to hire IT Developers in Vietnam

- Malaysia: How to hire employees in Malaysia

- Thailand: How to hire and find talents in Thailand

- Philippines: How to hire and find talents in the Philippines

- Singapore: How to hire tech talents in Singapore

- Indonesia: How to hire and find talents in Indonesia

Conclusion

Mastering the PDCA cycle is essential for any organization that wants to achieve continuous improvement and long-term success.

By following the four steps of Plan, Do, Check, and Act, organizations can identify opportunities for improvement, make data-driven decisions, implement changes effectively, and monitor progress to ensure that the changes are having the desired effect.

However, the PDCA cycle is not without its challenges.

Lack of data, resistance to change, inadequate resources, lack of accountability, and siloed departments are just a few of the obstacles that organizations may face when implementing the PDCA cycle.

But with the right approach, these challenges can be overcome, and the PDCA cycle can be an effective tool for driving continuous improvement.

In order to successfully implement the PDCA cycle, it’s important to invest in the resources and tools necessary to collect and analyze data effectively.

It’s also crucial to communicate the benefits of changes clearly, involve employees in the process, and establish clear roles and responsibilities.

By doing so, organizations can hold team members accountable and allocate resources effectively to ensure that the PDCA cycle is implemented successfully.

Finally, it’s important to remember that the PDCA cycle is not a one-time event but rather a continuous process of improvement.

By consistently following the steps of Plan, Do, Check, and Act, organizations can achieve long-term success and adapt to changing circumstances.

Mastering the PDCA cycle is a critical component of any organization’s strategy for achieving continuous improvement.

By understanding the steps of the cycle, overcoming common challenges, and committing to ongoing improvement, organizations can achieve their goals, improve their processes, and stay ahead of the competition.

If you find this article useful, why not share it with your family and friends and also leave a nice comment below?

We, at the 9cv9 Research Team, strive to bring the latest and most meaningful data, guides, and statistics to your doorstep.

If you are looking for a job, then hop to 9cv9 Modern Job Portal to find the best jobs and internships.